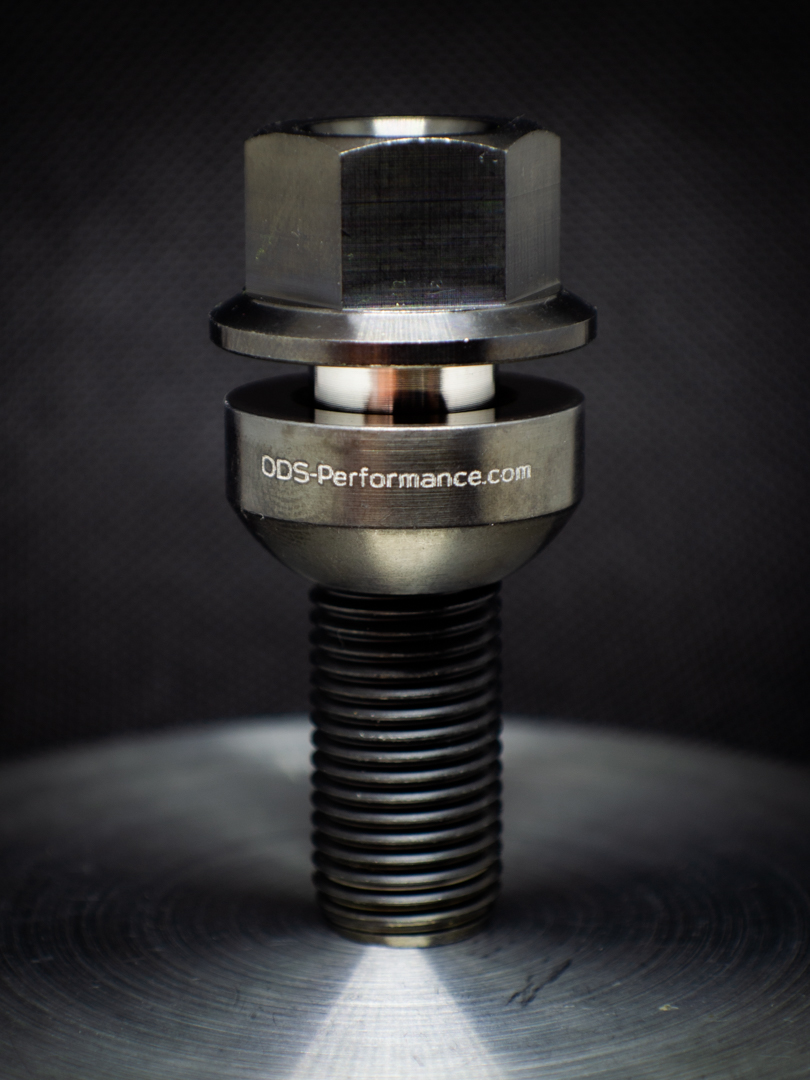

Titanium Wheel Bolts [STD, Black]

$465.00

- Box of 20 Light Weight, standard length black titanium wheel bolts for your Porsche

- 56.5g vs stock 93.7g

- 6Al-4V, Grade 5 Titanium

- 7075 Hard anodized aluminum seat

- Rolled Threads

- Lab tested to be superior to stock and competitors

- Comes in wood box with high density foam for storage and display

Description

Light weight, high strength titanium lug bolts to maximize power delivery of your Porsche while maintaining its sharp appearance indefinitely. Another titanium lug bolt? Why did ODS think this needed to be brought to the market?

First, the reasons for titanium lug bolts in general, then I will get into what makes the ODS Performance lug bolt different and better than the competition.

The most obvious reason to go with Titanium lug bolts is that they are much lighter than the stock lug bolts. 6Al-4V, Grade 5 titanium is renowned for having incredible strength at a given weight. Compared to standard steel bolts, 6Al-4V are over 40% lighter. Other advantages it has over steel are a slightly higher melting point and lower CTE (thermal expansion). In this application, those last two really are not going to matter much. But still worth noting. Another major benefit of titanium over standard bolts would be its incredible resistance to corrosion. Factory Porsche wheel bolts tend to look terrible after months of use where titanium ones will look almost new for years. With that being said, corrosion is a primary fault of all other aftermarket titanium bolts and nuts on the market. While titanium is very corrosion resistant, when it comes in contact with aluminum, such as wheels, the aluminum will actually corrode.

This brings us to what makes ODS Performance bolts different and what advantages our bolts offer. ODS Performance bolt seats are hard anodized providing a thick oxide layer that acts as a barrier thereby mitigating the galvanic action between the different materials. Bolts that utilize titanium seats will damage your expensive wheels. The time this takes to occur depends a lot on your environment. It can occur very quickly in salty and/or humid climates. As mentioned earlier, the main advantage of titanium is its weight. So why then would a wheel bolt manufacturer use a titanium seat that is heavier than even the factory aluminum seat, and damaging to your wheels? Either out of lazy engineering or simply not knowing another way. That is not how ODS Performance operates. There is no reason to make a part if we can not improve upon it. We spent the time to come up with a manufacturing process that allows the seat and bolt to be made from different materials utilizing different process then combine them to make a superior assembly. We combine the high strength titanium bolt with a hard anodized 7075 aluminum seat. 7075 aluminum is a very strong and light material. Perfect for this application, and using it saves nearly 40% of the weight over a titanium seat. ODS Performance only offers bolts with rolled threads which are stronger due to compressing the material instead of cutting it to form the threads. This provides a smoother better feeling thread which torques more consistently. Our wheel bolts also incorporate a specially designed transition at the head that increases fatigue life of the bolt. ODS Performance bolts take advantage of a shorter bolt seat so that the bolt head doesn’t stick out of the wheels as far as the factory bolt and most aftermarket bolts do. This not only looks better, but saves even more weight due to having an overall shorter assembly, even if the difference is very small. It is these details that matter.

Rather than just copying the factory bolt and changing the material to titanium, we engineered superior solutions into our design and came up with a manufacturing process unique to our bolts that enables us to maximize strength and performance, while minimizing weight. Lab testing backed up our FEA results showing that not only are our design and materials superior to other titanium bolts on the market, but even surpassed the performance of the factory bolts. ODS Performance takes these extra steps to ensure our finished product is the best possible option for your Porsche. And to top it off, our bolts are supplied with a stylish and convenient way of storing them or your stock bolts while you are using your superior ODS Performance bolts. And they just look so good.

Additional information

| Weight | 3 lbs |

|---|---|

| Fitment | 1999+ 911 all exc. GT2 & GT3 |

![Titanium Wheel Bolts [+5mm, Black] Qty: 10](https://ods-performance.com/wp-content/uploads/2019/10/5BlackBolt-3-300x300.jpg)

![Titanium Wheel Bolts [+5mm, Black] Qty: 10](https://ods-performance.com/wp-content/uploads/2019/10/5BlackBox-2-300x300.jpg)

![Titanium Wheel Bolts [STD & +5mm, Silver]](https://ods-performance.com/wp-content/uploads/2019/10/SilverBox-300x300.jpg)

![Titanium Wheel Bolts [STD & +5mm, Silver]](https://ods-performance.com/wp-content/uploads/2019/10/Long-Silver-300x300.jpg)

![Titanium Wheel Bolts [STD, Silver]](https://ods-performance.com/wp-content/uploads/2019/10/SilverBolt-300x300.jpg)